Reference materials are essential for accurate analytical measurements and quality control . Our aluminum reference materials enable our customers to assure the high quality they expect from their analyses using spark optical emission spectroscopy. Our reference materials are frequently used for determining measurement uncertainty, for calibration, recalibration and for validation of methods, suitability testing and quality assurance. The use of certified reference materials for quality assurance is required for accredited testing and calibration laboratories according to ISO/IEC 17025.

When analyzing aluminum alloys using optical emission spectroscopy the use of reference materials is an important step for a trustworthy analysis . Selecting the right reference material for your analytical task can be challenging. We try to explain you in the following how to get to the right reference material for your purpose .

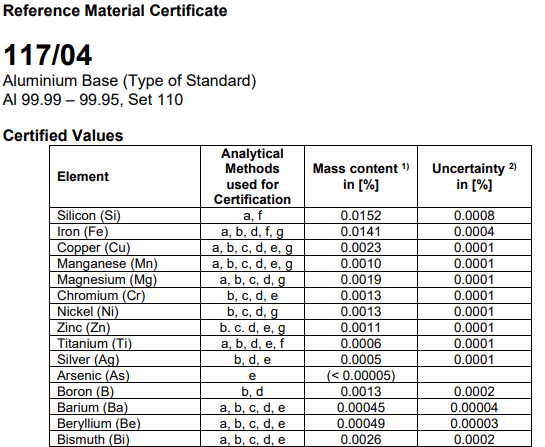

You may select your reference material by grade, by major elements or by concentration specifications. Typically, the certificate of analysis of all our reference materials list the major alloying elements first : Si, Fe, Cu, Mn, Mg, Cr, Ni, Zn and Ti. These are the elements that vary significantly in concentration in order to create different families of both cast and wrought alloys available. Additional elements are usually listed in alphabetical order after the main elements.

There are basically two types of aluminum reference materials available. The setting up samples which are also sometimes called monitor samples and the certified reference materials called CRMs. Below you’ll find the differences and the use for each.

These materials usually contain a relatively large array of elements . Elemental concentrations are not certified and only given as approximate values. There are no uncertainties reported. In Suisse TP's certificate those values are reported in parentheses. Homogeneity of setting-up samples are within tight boundaries and analytical intensities gathered from these materials are very stable . SUS are an interesting lower-cost option for daily standardization and drift correction . They should never be used for calibration purposes since the elemental concentration is not certified .

At the catalogue a range of specialized setting up samples can be found which are intended to calculate the correction of the deviation of multi-channel spectrometers. The production of such materials has been optimized to obtain the best possible homogeneity, taking into account their composition.

Consequently, the setting up samples are capable of giving a highly reproducible spectrometric signal for the indicated elements.

Their use, at a frequency which is a function of the stability of the spectrometer, permits the measurement and correction of significant variations undergone by the spectrometric response of these elements (deviation correction). The setting up samples are necessary to accomplish quickly the "standardization" of spectrometers equipped with calculators; they comprise in a small number of alloys high points and a low point for standardization and drift correction of all the channels.

Setting up samples with limited number of elements in concentrations close to the alloy that is to be measured are sometimes called monitor samples .

WARNING : Compositions in these samples are not verified by chemical means. These setting up samples can on no account replace the usual CRM used for calibration.

In the certificates of analysis for certified reference materials the concentration and uncertainty for each certified element is given. These values are usually based multiple wet chemical analyses in some cases from different laboratories. Certified reference materials from Suisse TP are certified in house using several analyses to provide statistical data for uncertainty determination.

CRMs can be used for instrument calibration but also verification of calibration . There are CRMs with only the major elements certified or CRMs that offer certified values for almost all elements that may be present in aluminum alloys. Make sure you choose the CRM with elemental concentrations similar to the alloys you are analyzing. Should you need to proof the absence of elements in your alloy make sure you possess a CRM that contains these elements in a concentration right at or slightly below the limit for this element. Only with such a standard you can proof that you would actually detect the element should it be present in your alloy.

Should you need to determine the content on minor elements (not the absence of an element), make sure the CRM you are using has a slightly higher concentration of the element in question so that your measurement takes place in a calibrated range. It is not good practice to extrapolate calibration to higher content.

Reference materials for the analysis of aluminium alloys by spark optical emission spectroscopy or XRF are usually produced by casting. In most cases, a continuous casting process is applied followed in some cases by hot extrusion to the final diameter. The casting process is critical since it determines the homogeneity of the reference material. Cast shops for this delicate task are carefully evaluated and selected.

Casting lots can be of different size. The prices vary depending on the amount of certified elements as well as on the size of the lot. When the perfect lot is casted the material needs to be certified by various methods.

Certification analyses for our standards are done in our in house analysis lab. Our lab is accredited by the Swiss Authorities as a test facility for the chemical composition of metallic materials in accordance with the International Standard ISO/IEC 17025:STS0023 . The analysis methods are based on internationally accepted analytical procedures. Some of them were developed by the Aluminum section of GDMB (GDMB Gesellschaft der Metallurgen und Bergleute e. V.). Single element standards from ISO 17034 accredited producers are used in the course of the analysis for calibration of the analytical instruments. During all these procedures, traceability of the analysis back to national standards is ensured.

The analytical lab of Suisse TP is regularly participating in proficiency tests from ISO/IEC 17043 accredited bodies. These programs ascertain and underlie the high quality of our analyses.

The values listed in the analysis certificate of each certified reference material, accompanied with each delivery, are based on the results of usually at least 2 independent analysis method and multiple analyses performed with each method.

Suisse TP is also able to certify customer materials . If a homogeneous rod in a suitable diameter and lengths of a special customer alloy is available, Suisse TP can analyze homogeneity and the concentration values of all or selected elements and issue a certificate. Ask for an offer for such an analysis!

If you buy certified reference materials you expect to get a very homogeneous material. You may expect stable analysis values. Since the certification process is based on multiple wet chemical analysis results, the reported uncertainty on the reference material certificate is relatively small compared to the measurement uncertainty of optical emission spectroscopy. Since for the final analytical uncertainty the uncertainty margin of the CRM is also taken into account, a small uncertainty of the reference material is positive for the final analytical uncertainty.

The uncertainty reported on our certificates represent the half width confidence interval C(95%), where C(95%) = (t x SM / √n) and “t” is the appropriate two sided Student’s t value at the 95% confidence level for “n” acceptable mean values.

Homogeneity testing is performed by means of spark emission spectroscopy. Tests involve making multiple measurements on individual samples taken at regular intervals along the entire length of each cast rod. Depending on the mass content of the element, the relative standard deviation of multiple measurements between discs or within one disc is typically found between 0.3% - 1% for alloying and other elements and 0.5% - 5% for trace elements.

Traceability of the certified mass contents to the SI (Système International d’Unités) is ensured by calibration using certified standard solutions (from trusted, ISO 17034 accredited sources) or pure metals or substances of known stoichiometry.

Values in brackets ( ) are not certified but given for information only. These values should never be used for calibration of an analytical instrument.

There are certain elements, such as Na, Ca or Li that tend to evaporate during the cast. This would increase the uncertainty of the certified values significantly and make the CRM useless for these elements. In this case, there is a range of concentration given for these elements on the certificate. Individually certified values for those elements for each disc are available on S-certificates only. Add an "S-Certificate" to your shopping cart together with your article, to get individually certified values for those elements.

Our certified reference materials are primarily intended for use in spark optical emission spectroscopy. Other applications are X-ray fluorescence spectrometry (XRF) and classical wet chemical procedures. The minimum sample size for wet chemical analysis is 0.2g. The material will remain stable for the period given (certification validity) if it is stored in a dry and clean environment at room temperature.

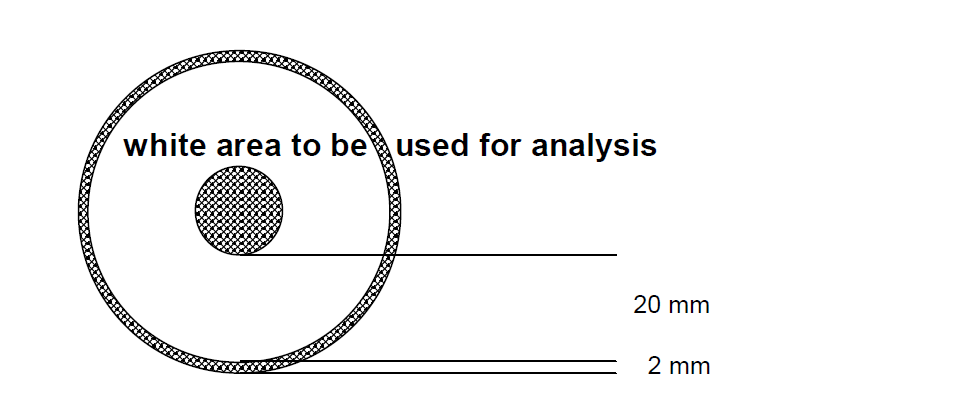

Calibration measurements should be made within a ring between 2mm and 22mm from the edge of the CRM face. For wet chemical analysis chips have to be prepared by turning or milling of the sample surface. Also in this case, chips should only be taken from the white area.

Certified reference materials may be used for basic system calibration, which is usually done by a service technician of the system. They may also be used for regular performance checks of the system. Depending on the stability of the system, such check may be required in varying intervals. Drift check during long measurement series or stability check at shorter intervals may be done by measuring setting up samples. These samples are homogeneous and deliver stable intensities for the individual element. However, absolute values are not certified. If such a standard is replaced by a new sample, the new sample needs to be measured together with the old and set as the new standard to which stability and drift is compared.

When using a CRM, the element concentration needs to be in a similar concentration range than the elements you want to analyze. It may be difficult to always find exactly the CRM that matches your application. So, a combination of several CRM for checking the performance of your instrument needs to be used. In such a case, make sure, elements that may influence each other (interferences) need to be present in the same CRM in a reasonable concentration so you may see such behavior of your instrument.

If your application requires that you proof the absence of some elements in the alloy, make sure you use a CRM where these elements are present in a concentration at or below the limit you need to guarantee. Only with such a CRM you may proof that your system would actually detect the element, should it be present. This is the reason, why many CRM have also minor elements certified in low concentrations.

If you already know the name of the reference material you need, use the searchbox in the left column on every page. If the desired product is not available any more, there will be a recommendation for an alternative product. If the product is a successor you’ll find an index after the “/”. For example 122/03 is the third reproduction of the product 122 and replaces 122/02. Sometimes we also recommend other products if they can be used as an alternate product.

If you are looking for a specific composition, you can enter the elements with the concentration you wish. If you need a CRM e.g. according to EN AW-6063 (EN AW-AlMg0.7Si) which means Si shall be 0.2% - 0.6% and Mg shall be 0.45% - 0.9% try searching like this:

Element: Si mass content (%):0.4 search tolerance (+-%):50

Element: Mg mass content (%):0.7 search tolerance (+-%):30

Click on search to receive a list of CRMs that match your search criteria. If the choice is too big decrease the tolerance, if there are no results increase the tolerance.